R&D

- >

- Quality

- >

- R&D

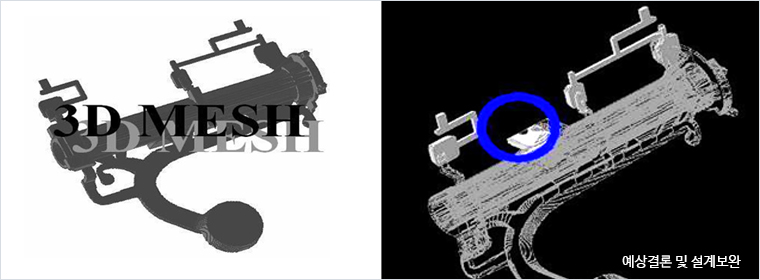

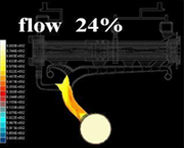

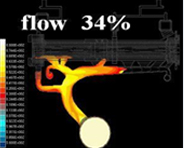

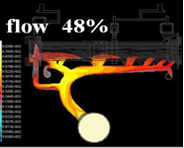

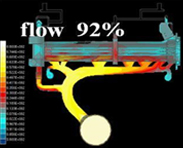

Fluid Flow Simulation

- In case of a complex product, we design its mold and understand its structure based on prior simulation

- Materials

- Pouring Temp

- Mold

- Mold Temp

- ADC12

- 700℃

- SKD61

- 200℃

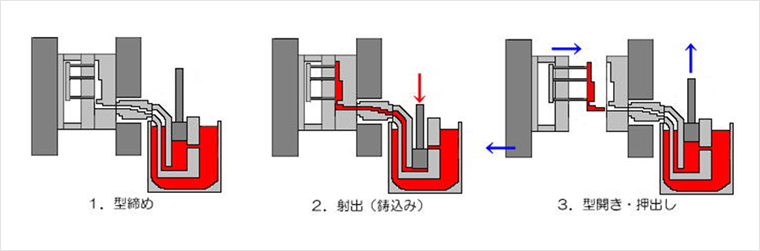

Casting deal drawing

Features of Hot chamber die casting

1. Mainly used for casting Zn, Sn, Pb, and Mg alloys. 2. You can create a casting in a thin and complex shape. 3. No need for pouring because the injection part is in a molten metal and casting cycle is fast; 750 times/ h 4. You can inject the molten metal with a plunger as the compression cabin is in a smelting furnace. 5. Low casting pressure (7MPa ~ 25MPa) due to the structure of the compression cabin. 6. Less oxides and air flowing into.